Welcome to the official website of Exent (Nanjing) Security Technology Co., Ltd.!

Welcome to the official website of Exent (Nanjing) Security Technology Co., Ltd.!Balanced proportional mixing device

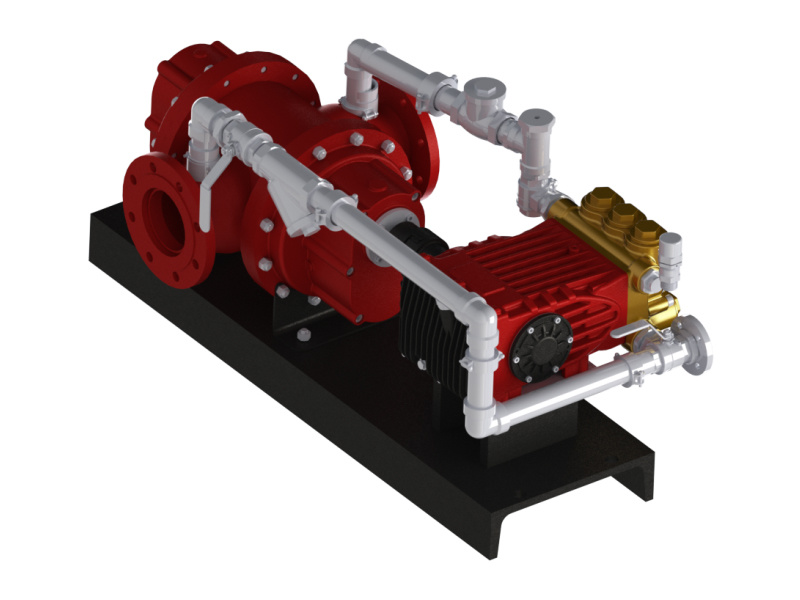

We are committed to the research and development of the new foam proportional mixer to make it as suitable for all foam fire extinguishing systems as much as possible. On the basis of referring to some international proportional mixer data, we have independently developed a new hydraulic motor and plunger pump. The flow range of the proportional mixer is wider, the pressure loss is smaller, and the service life is longer.

Key words:

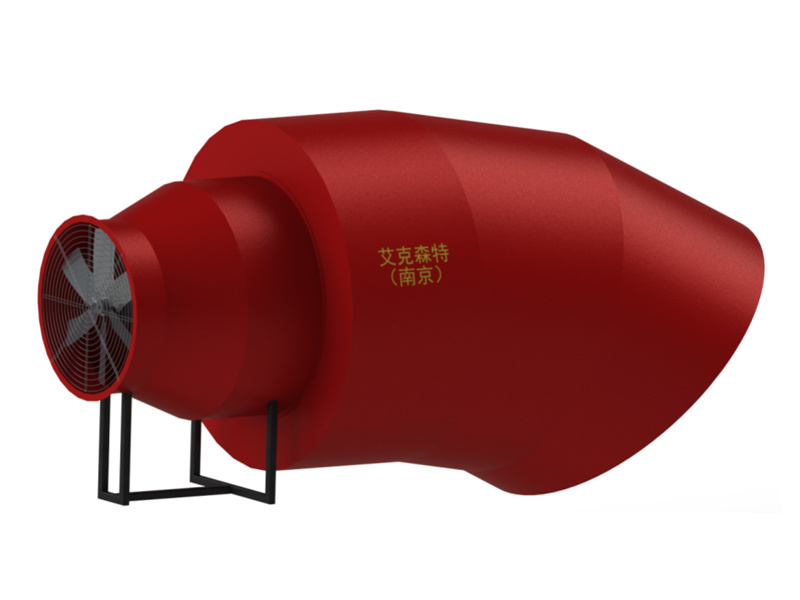

Mechanical pump-in proportional mixing device/balanced proportional mixing device/high-expansion fire extinguishing system generator

Classification:

Foam system

- Describe

-

- Commodity name: Balanced proportional mixing device

We are committed to the research and development of new foam proportional mixers, making them suitable for all foam fire extinguishing systems as much as possible. The flow range of the device is wider, the pressure loss is smaller, and the structure is more compact.

product description

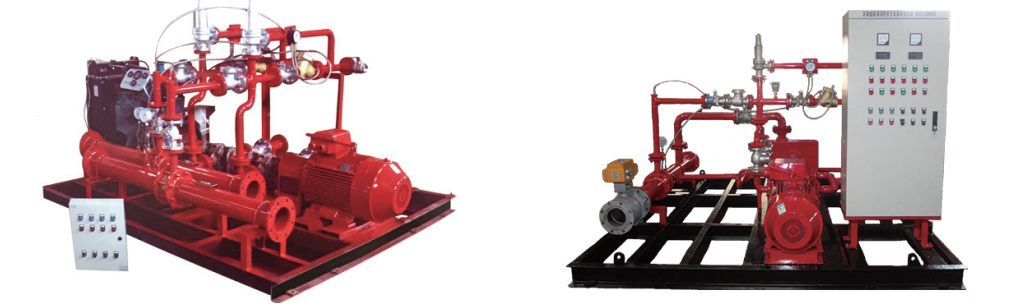

The foam proportional mixer is the core of various foam fire extinguishing systems, and the accuracy of the mixing ratio directly affects the fire extinguishing effect. There are many types of foam proportional mixers, such as pressure type, balanced type, ring pump type and metering injection type, etc., each type of proportional mixer has its own application, advantages and limitations.

We are committed to the research and development of new foam proportional mixers, making them suitable for all foam fire extinguishing systems as much as possible. The flow range of the device is wider, the pressure loss is smaller, and the structure is more compact.

Our experienced engineers have comprehensive knowledge and rich practical experience on various types of foam proportional mixers and various types of foam fire extinguishing systems, combined with design calculation theory, and hundreds of experimental verifications, to achieve high-performance ratio mixing device.

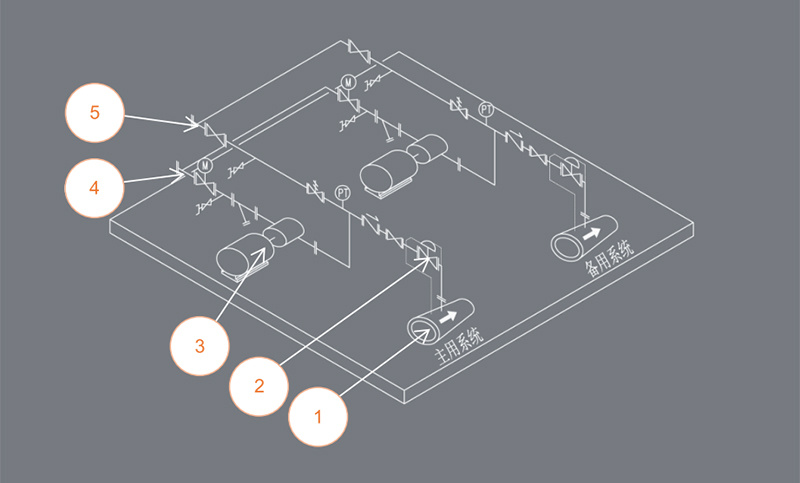

① Proportional mixer ② Balance valve ③ Foam pump 4 Foam inlet pipe ⑤ Foam return pipe

working principle

When a fire occurs, the fire pump is started automatically or manually, and the balanced proportional mixer ① has pressure water flowing through it.

The foam liquid inlet pipe ④ electric valve is opened remotely by the fire control center or the automatic control cabinet, and the foam pump ③ is started, and the foam liquid stored in the normal pressure foam tank is injected into the proportional mixer ① by the foam liquid pump.

After the foam liquid is automatically adjusted by the balance valve ②, an appropriate amount of foam liquid enters the proportional mixer ① and is mixed with pressure water at a ratio of 3:97 to form a foam mixture.

Then supply foam generating equipment for fire fighting through pipelines, such as foam guns, foam guns, foam generators, etc., to generate air foam to extinguish Class A, B, and C liquid fires.

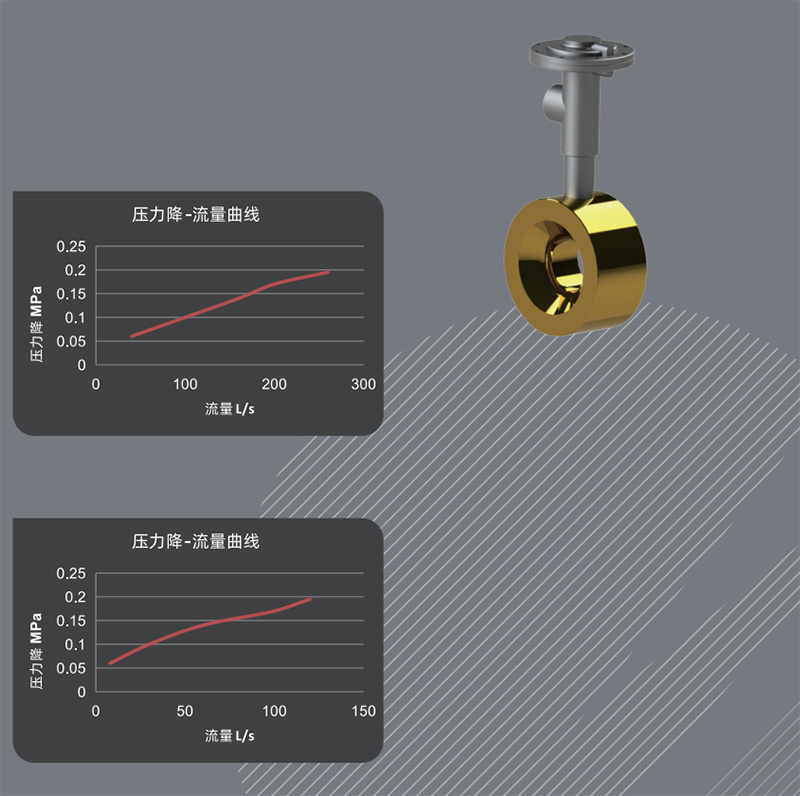

performance curve

Advantages

• Dynamically adjust the foam liquid volume of the foam proportional mixer through the balance valve to ensure the precise mixing ratio;

• The stainless steel foam liquid pump supplies the foam liquid, so that the working pressure and flow of the foam mixture have a large adaptable range, and will not rust due to the corrosion of the foam liquid;

• Atmospheric pressure, non-capsule foam liquid storage tank, easy maintenance and high reliability;

• The breather valve maintains the pressure balance inside and outside the foam liquid storage tank;

• Emergency pressure relief of the safety valve ensures the safety of the pipeline of the device;

• The device is suitable for all types of foam fire extinguishing agents (protein, fluorofoam, aqueous film-forming, etc.);

• Foam liquid can be added at any time during the fire extinguishing process, which can better meet the needs of modern large-scale foam fire engineering;

• The device adopts automatic/manual switching control, which is easy to operate.

Technical performance parameters

serial number model nominal diameter Flow range

(LPM)Working pressure range

(bar)Mixing ratio

(%)1 PHP40-BE DN80(3") 180~2400 5~16 3 or 6 2 PHP66-BE DN100(4") 240~3960 5~16 3 or 6 3 PHP100-BE DN150(6") 480~6000 5~16 3 or 6 4 PHP170-BE DN200(8") 480~10200 5~16 3 or 6 5 PHP200-BE DN250 (10" ) 960~12000 5~16 3 or 6 6 PHP330-BE DN300 (12" ) 1440~19800 5~16 3 or 6 NOTE: 1. HG/T20592, ASME B16.5 and other implementation standards can be provided for the butt joint flanges of all specifications.

Related Products